Spray Tank Adjuvants.

A spray or herbicide adjuvant is an additive that improves the effectiveness of a turf chemical or fertiliser. Spray adjuvants include defoamers, spreaders, stickers, and water conditioners. These:

- Wet surfaces faster.

- Give a more even product distribution over the leaf.

- Increase the retention of a spray on a leaf, and improve foliar uptake.

What are Spray Tank Adjuvants?

- Spray and herbicide adjuvants are compounds that you add to a spray tank. These improve how well a chemical mixes, how it behaves on a leaf or how well it works.

- Some glyphosate formulations such as (Rapid Fire) already include an adjuvant. In other cases, these are stand-alone herbicide adjuvants that you add to a spray tank.

- The use of adjuvants is common in Sydney and Canberra due to the unique climates that turf managers face.

Adjuvant examples:

- Some herbicide adjuvants counter issues with hot dry weather, that can affect herbicide performance.

- Others lower a spray tank pH so that products work better.

- A non-ionic surfactant is recommended with Proforce Duke herbicide, or Recondo herbicides. These are both sulfonylurea herbicides. The use of a herbicide adjuvant with these improves leaf coverage, and so gives better results.

At the end of this article is a list of adjuvants to use with turf products.

Check these links out for more on soil adjuvants and Soil wetting agents. For more detail on what adjuvants you can use with which turf chemical see this Turf Chemical Guide.

Do Spray Adjuvants work?

The simple answer is yes, but only if you use the right one. For an example of how effective herbicides adjuvants can be, I’m going to use Quinclorac the active in Quinstar.

- Quinclorac with no adjuvant does not control Sowthistle1Zawierucha, JE. 1998. The Basis for the Differential Response of Several Weed Species to Quinclorac. Michigan State University. Department of Crop and Soil Sciences.

- All adjuvants give better control with Quinclorac except for a modified polysiloxane.

- Quinclorac works nearly twice as well on Green Foxtail when you increase the spray pH from 2.6 to 7.32Woznica Z, Nalewaja JD, Messersmith CG, Milkowski P. Quinclorac Efficacy as Affected by Adjuvants and Spray Carrier Water. Weed Technology. 2003;17(3):582-588. doi:10.1614/0890-037X(2003)017[0582:QEAABA]2.0.CO;2.

The Benefits of Spray Adjuvants:

- They help products mix better in a spray tank.

- They improve the contact between a chemical and the target.

- Water conditioners improve how well a chemical works.

- Herbicide adjuvants increase the rate a chemical moves through the leaves and the stomata.

- Adjuvants increase chemical safety. They increase chemical selectivity.

- They can reduce the chemical rate by 5 to 10 times and reduce costs.

- An adjuvant costs a lot less than a chemical does. A USA study shows that the use of adjuvants can reduce costs by up to 40%.

In many cases use of these improves how well a turf chemical works. The graph below shows how these can improve the performance of Azoxystrobin.

Thanks to the USDA Agricultural Research Service for these videos.These show how the right adjuvant can improve chemical movement into a leaf.

The Negatives of Spray Adjuvants.

These can also be some negatives when you use these.

- They can reduce how well a chemical works. For example a water conditioner or pH buffer, doesn’t always improve the results you get.

- They can extend the life of a chemical so it takes longer to breakdown. This means they persist longer in the environment.

- Some are even dangerous themselves. This was the case with the carrier in older Glyphosate formulations.

In fact there is no perfect spray adjuvant. Nothing will always make a chemical perform better in all situations.

History of Spray Adjuvants.

Below is the 2013 APVMA data for chemical use. This is by dollar value, vs the 2020-21 figures. Both the number of products, and the value of adjuvant sales show a huge increase.

When these products were first introduced they had little data to support their claims. These were simple soaps, as well as vegetable, and petroleum-based oils.

However, over time there has been a significant amount of investment. This has lead to major advances in understanding how these products work.

| Product type | No of products 2013 | Total Sales $m 2013 | No of products 2020-21 | Total Sales $m 2020-21 |

| Adjuvants/surfactants | 375 | 83.5 | 438 | 139.6 |

| Fungicides | 703 | 218.1 | 1165 | 351.7 |

| Herbicides | 2,420 | 1302.7 | 3927 | 2244 |

| Insecticides | 1,166 | 425.8 | 1588 | 458 |

How to Use Spray Adjuvants.

These have several modes of action. For example, they can increase the retention, spread, and movement of chemicals into plants. Some, also have the ability to affect spray droplet size, reduce foam or even alter the water pH.

Activator Spray Adjuvants.

These improve chemical performance. They can for example, increase the uptake of a chemical. Surfactants, crop oils, crop oil concentrates (COCs), vegetable oils, methylated seed oils (MSOs), petroleum oils, N fertilisers, and silicone derivatives, are all in this class.

Spray Modifiers.

Spray modifiers include spray stickers, spreaders, and drift control agents. These change the physical nature of a spray solution.

Utility Adjuvants.

Ultility adjuvants include products like defoamers, spray buffers, and water conditioners. These increase the conditions where you can use a turf chemical.

Spray Adjuvants in turf | |||||

Activator Adjuvants | Utility Adjuvants | ||||

Wetter/Spreader | Sticker | Humectant | Penetrant | Defoamer | Water conditioner |

Surfactants (Spreader 90LFor Scrubwet) | Octane | Glycerin | COC's or MSO's | Anti-foam (Foam Aid) | Crystalline AS or Manta Ray |

Surfactants.

- These are the most common group of spray adjuvants.

- The term Surfactants comes from SURFace ACTive ageNTS.

- They reduce the surface tension of a spray solution, and how a spray behaves.

- You often find these in use as herbicide adjuvants for weed sprays.

- If you reduce the surface tension of water, the solution spreads out over the leaf, and does not bead on the surface.

The surface tension of water is 72 dynes/cm. Surfactants reduce the surface tension down to 20 to 30 dynes/cm. This reduction in surface tension means better uptake as the spray is in contact with the leaf surface for longer.

This is the reason why you use non-ionic surfactants for Duke herbicide, Recondo or Tribute Selective.

Examples of non-ionic surfactants include: EO-PO Block copolymers, organo-silicones, and alkylpolyglucosides (APG).

Surfactants also change the viscosity, and structure of leaf and stem waxes. This makes it easier for a herbicide to enter the plant.

How Do Spray Surfactants work.

- They allow a more uniform spread of the spray solution over the leaf surface.

- Spray surfactants act as spray stickers.

- They increase the movement of chemicals past leaf hairs etc.

- They prevent spray deposit crystallisation.

- Increase the time for a solution to dry, and water retention.

Several factors affect the results of a spray application. Key amongst these are:

- The nature of the target plant.

- Any interactions between the adjuvant and a chemical.

The balance between the hydrophilic (water-soluble) and lipophilic (oil soluble) components of an adjuvant is called the Hydrophillic –Lipophilic Balance (HLB).

The HLB is a key factor to consider when you choose a product. It is a way to describe how much a surfactant loves water (hydrophilic) or oil (lipophilic).

- If you match the HLB of an adjuvant to the chemical nature of a pesticide and the target, it ensures you get better results.

- It is best to use a lipophilic adjuvant with a lipophilic chemical and vice versa.

- Oil soluble herbicides work best with herbicide adjuvants that have an HLB of 1 to 10.

- Water soluble herbicides work best with surfactants with an HLB of 10 to 20.

Table of HLB Ranges for Spray Adjuvants.

Best For | Herbicides: Group 1: Destro; Group 5: Metric, Xtron, Renegade Quinstar | Herbicides: Rapid Fire, Exonerate, Duke, Recondo. Fungicides: Voltar Most surfactants with postemergents HLB values >12 Ethephon Clofentazine | ||||||||||||||||

Adjuvant type | MSO Spray oils (2-5% surfactant) | Crop oil concentrates (15-20% surfactant) | NIS & Manta Ray | |||||||||||||||

HLB value | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 |

Lipophilic (oil soluble) | Water dispersible | Hydrophilic (water soluble) | ||||||||||||||||

Product Type | anti-foam | wetter/ spreader | detergents | |||||||||||||||

water in oil emulsifier | oil in water emulsifier | |||||||||||||||||

How it looks in water | no dispersion | unstable milky dispersion | see through to clear dispersion | |||||||||||||||

Poor dispersion | Stable milky dispersion | Clear solution | ||||||||||||||||

There are three main types of spray adjuvants for turf:

- Nonionic (no charge).

- Anionic (negative charge).

- Cationic surfactants (positive charge).

Both anionic and cationic surfactants are not often used on turf, because they can cause damage to turfgrass.

Non-ionic Surfactants.

- Non-ionic surfactants are the most common of these. As well as being hydrophilic (they love water), they do not have an ionic charge. This means they tend to have no negative effect on a spray mix. All wetters, spreaders, and organosiloxanes are in this class.

- Non-ionic surfactants reduce the surface tension of a spray solution. They have a direct effect on the leaf cuticle, and change the nature of a leaf surface.

- When you use Organosiloxanes (Proforce Scrubwet), they reduce the surface tension, and form a thin layer on the leaf surface.

- Their unique properties, mean that these are often included as wetting agents for weed sprays. Spray solutions are able to move through the stomata, and they effect the amount of chemical that passes through the cuticle.

- This super spreading property means that they are nearly impossible to wash off a leaf surface. Even if it rains.

- Organosilixone adjuvants improve the uptake of phosphorous acid into Pinus radiata needles3Rolando C, Gaskin R, Horgan D. et al. The use of adjuvants to improve uptake of phosphorous acid applied to Pinus radiata needles for control of foliar Phytophthora diseases. N.Z. j. of For. Sci. 44, 8 (2014). https://doi.org/10.1186/s40490-014-0008-5.

- Ongoing work is even looking at these to help with the control of adult stem weevil.

Oils.

The three types of oil-based adjuvants are:

- Crop oils.

- Crop oil concentrates.

- Methylated seed oils.

These are popular as a herbicide surfactants because they increase the movement of a spray into a plant, and reduce surface tension.

Crop Oils.

- These are also known as petroleum oils, but do not contain any vegetable oil.

- They contain a maximum of 5% surfactant.

- Crop oils, improve the movement of a chemical either through a plant’s waxy cuticle or an insect’s tough, chitinous shell.

- You often see traditional crop oils in use for insect and disease control, and rarely with herbicides.

Crop Oil Concentrates (COCs).

- These contain 10 to 20% non-ionic surfactant.

- COC’s act as penetrants and are excellent spreading agents.

- They are good herbicide adjuvants. They help make some of the less-soluble herbicides more soluble in water.

- They are often used to target grass weeds like Summer Grass.

- Examples are Hasten and Banjo spray adjuvant. Both of these are a combination of vegetable oil and non-ionic surfactant.

Methylated Seed Oils (MSOs).

- These are oil-based surfactants, and can cause leaf burn and phytotoxicity.

- Examples include Voltage MSO.

- These are the most active of the herbicide adjuvants. They work best on large weeds or those under drought-stress that are not growing.

This type of herbicide surfactant has the following benefits:

- When you use this theset they increase the drying time on a leaf surface. This increases the time for herbicide uptake.

- These herbicide adjuvants solubilize leaf waxes. This improves chemical penetration of a leaf.

- They improve the control of large weeds.

- You get better control of weeds under stress or that are not growing.

- These work well on difficult to control weeds.

MSO’s improve the performance of Quinclorac when you use it for Spurge or Summer grass. This is because an MSO + Quinclorac does two things:

- It enhances chemical movement into the leaf.

- They keep a chemical in solution. This prevents it from crystalising on the leaf surface.

- You need 25% less Nominee for Winter Grass control when you use it with an MSO spray adjuvant4Lycan, DW. & Hart, SE. (2005). Cool-season Turfgrass Response to Bispyribac-Sodium. HortScience, 40(5), 1552-1555. https://www.doi.org/10.21273/HORTSCI.40.5.1552.

Water Conditioners or Spray Buffers.

- The ideal water pH for most chemicals is in the range of 4.0 to 6.5, and it is best between 5.5 to 6.5.

- Most chemicals work better in the 4 to 6.5 pH range due to alkaline hydrolysis.

- Above a pH of 7, some chemicals tend to be prone to this.

- An example of this are iprodione-based fungicides like Voltar® 500SC. This has a half-life of 48 minutes at pH 7.

- An outlier to this are the Group 2 herbicides, which favour a pH of 7 or greater.

- When you use a water conditioner or spray buffer like Manta Ray it lowers the water pH. This means it is ideal to use as a surfactant for herbicides like Glyphosate.

- The end result is fewer re-sprays, better performance, lower chemical use and lower labour costs.

Water pH.

- Water quality changes through the year so you need to check it regularly.

- Generally speaking tap water in Australia is at a pH of above pH 7.

- If you use water at this pH in your spray tank you may need to use a spray buffer.

- Do not get into the habit of using a spray buffer in every tank mix. For example, at a low pH, 2,4-D amine tends to drop out of solution or form a gel.

- If you don’t have a current water analysis there are some options. There are some great online tools available. Simply fill in your post code and it will give you the results.

South East Melbourne Water quality

South East Queensland Water quality

Table of Water pH Spray Tank Stability.

Active | Optimum pH | Alkaline pH 8-9 | Neutral pH 7 | Acidic pH 4-6 |

2,4-D amine | 4.5 | Unstable | stable | stable |

Abamectin | Stable pH 5-9 | |||

Azoxystrobin | Stable over a wide pH range | |||

Bifenthrin | Stable pH 5-9 | |||

Clofentazine | 4.8 hours | 34 hours | ||

Dicamba | 5.5 | Unstable | Unstable | Stable pH 5-6 |

Ethephon | < 5.0 | |||

Fosetyl aluminium | 6.0 | Stable pH 4-8 | ||

Gibberellic acid | < 7.0 | Do not mix with alkaline materials | ||

Glufosinate ammonium | 5.5 | |||

Glyphosate | 3.5-4.0 | |||

Imidacloprid | 7.5 | Stable pH 5-9 | ||

Iprodione | Breakdown above pH 8 | |||

Metalaxyl | Buffer to a pH <7.5 | |||

Pendimethalin | Stable | |||

Propiconazole | Stable at pH 5-9 | |||

Thiophanate methyl | 5-7 | Unstable | Stable | Unstable |

Anti-foam or Defoamers.

Defoamers reduce the build up of foam. This can be a serious issue in soft water areas like the ACT. Polydimethylsiloxane is the active in Foam-aid. It prevents foam, and removes any foam that forms while you mix.

Deposition and Drift Control Agents.

Deposition aids are also called spray stickers. These increase how long a chemical lasts, once you apply it to a leaf surface. Other properties include:

- They can reduce evaporation.

- Increase UV stability. Bond adjuvant or Octane are examples of these.

- Drift control agents reduce spray drift, by increasing the spray droplet size.

- Droplets with a diameter of 150 microns or smaller tend to drift. The use of drift control agents means you can better target your spray.

- They bind with water molecules to form larger spray droplets.

- The best of these appear to be products based on guar gum.

Since 2010 there has been a law to assess new chemicals for the potential risk of spray drift. As a result of this, no spray buffer zones are now on labels of products like Specticle herbicide and Numchuk Quad.

Modifying Spray Drop Size.

- Wetting agents tend to reduce the spray drop size.

- Oil-based adjuvants tend to increase it.

- When you spray, consider your nozzle selection, the spray pressure, boom height, and also the weather conditions.

- Don’t rely solely on these to deal with off-target drift.

- Water-based sprays are the standard means to apply chemical sprays.

- The aim is to use a specific-sized spray for the best results.

- Drift occurs if droplets are too small.

- If spray drops are too large they will run off the target.

Foam Markers and Colourants.

You use foam markers to see where you spray without having to use a marker dye. This helps avoid overlap when you apply chemicals.

You use colourants such as Blue spray indicator as marker or indicator dyes to identify areas that you have already sprayed. This is in contrast to turf pigments that you can use as broad acre masking agents, and also to stimulate growth.

Spray Tank Cleaners.

Spray tank cleaners remove nasty residues that remain after you spray. Tank cleaners often contain sodium tripolyphosphate. You should always use these to clean a spray tank if you use a non selective herbicides like glyphosate or the sulfonylureas.

Ammonium Fertilisers.

- Urea-ammonium nitrate (UAN), and ammonium sulphate (AMS) reduce the negative effects of hard water.

- Fe, Zn, Mg, Na, K, and Ca can react with herbicides like 2,4-D and glyphosate, to form insoluble precipitates.

- In hard water areas, you should consider the use of crystalline ammonium sulphate as a herbicide adjuvant. This will stop the formation of the insoluble Ca form of Glyphosate.

- Don’t use granular or standard ammonium sulphate with Glyphosate. This is because they both contain impurities that will give poor results.

- When you add crystalline ammonium sulphate as a herbicide adjuvant to a tank the temperature of the solution drops. This what is called an endothermic reaction.

- Because of this, be aware that in the Winter, this drop in temperature can make tank mixing difficult. For this reason, fill the tank at least three-quarters full before you use ammonium sulphate as a herbicide surfactant.

Our chemical and irrigation suitability water analysis calculates exactly how much ammonium sulphate you need.

Table of The Ammonium Sulphate Rate for Hard Water.

| Water hardness Ca2+ ppm | Water hardness level CaCO3 ppm | Liquid Boost (AMS) recommend mL/100L |

Equivalent amount of AMS Crystal g/100L |

| 80 | 200 | 250 | 104 |

| 120 | 300 | 375 | 156 |

| 160 | 400 | 500 | 208 |

| 200 | 500 | 625 | 260 |

| 240 | 600 | 750 | 312 |

| 280 | 700 | 875 | 364 |

| 320 | 800 | 1000 | 417 |

| 360 | 900 | 1125 | 469 |

| 400 | 1000 | 1250 | 521 |

| 500 | 1250 | 1565 | 652 |

| 750 | 1875 | 2345 | 977 |

- Turf is very efficient at taking up NH4 ions.

- This is because when turf takes up NH4 it is at the expense of H+ ions.

- When this happens the H+ ions tend to move to the outside of plant cells.

- When this occurs, there is a drop in the pH.

- The use of NH4 increases herbicide uptake, and creates a pH gradient across the cell membranes.

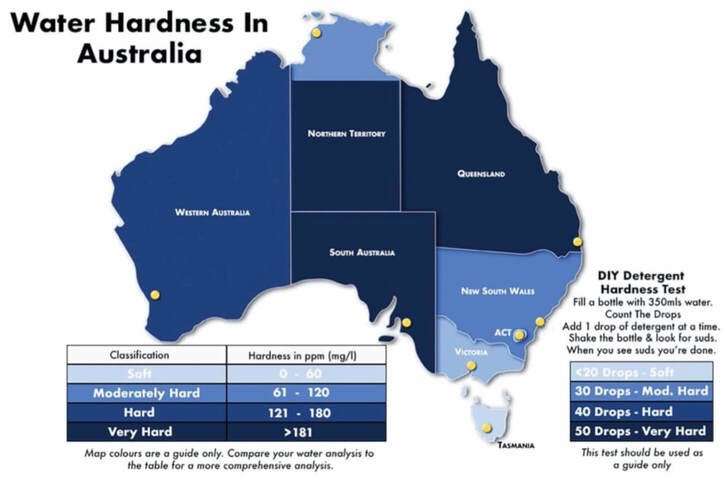

Map of Hard Water Areas in Australia.

Compatibility Agents.

- You use compatibility agents to avoid issues with chemical mixes. An example of this is the spray adjuvant Fix-it Tank Mix®.

Here is a method for a “jar test” to find out the stability of a mixture. Always remember to wear personal protective equipment (PPE) when you handle chemicals.

You will need a 1L or bigger glass jar. The key point to note is that how well a tank mix works, depends on how well the products mix.

Doing a Jar Test.

- Measure 500 ml of water into the glass jar. You want to use the same water source you use in the tank.

- The aim is to mirror on a small scale, what happens in your tank. Add the products you want to use in the same proportions.

- You need to do this one at a time, as per the label. If the rate is 10 Kg per 400 L then add 12.5 g to 500 ml of water.

- If there is no order to mix on the label, then add them in the order below.

- Each time you add a product, make sure you stir it well until you add the next one.

-

- Add your compatibility agent, buffer, or defoamer.

- Add wettable powders, dry flowables, and water-dispersible granules.

- Next add flowables, liquids, and micro-encapsulated products.

- Next add solutions and soluble powders.

- Then add any adjuvants that remain. This includes surfactants or crop oils.

- Add any emulsifiable concentrates.

- Liquid UAN.

4. Shake the jar and leave it for at least 15 minutes. The mixture is not compatible if:

- A scum forms on the surface.

- The mix separates out.

- Solids form and then settle to the bottom.

- Clumps or gels form.

- It gives off heat or a smell. If the jar feels warm to the touch and/or there is a strong smell don’t use the mix.

If issues occur, this mix is not compatible and you should throw it away.

How to Choose A Spray Adjuvant.

- Read the product label. Many labels list what to use, and in some cases these details are under the “Directions for Use” section.

- Use the active ingredient content to calculate the cost.

- Use a brand that has data to support its claims.

- Only use formulated products. If you don’t it may affect the chemical performance. So don’t use washing up liquid.

- If it makes claims that sound to good to be true, these probably are.

- You don’t always have to use an adjuvant.

- Make sure that your equipment is set up properly.

Spray Adjuvants For Turf Products.

Active | Product | Suggested Adjuvant | Adjuvant name |

Herbicides | |||

Clopyralid | Wallop 600 | Non ionic surfactant | |

Dicamba + Prosulfuron | Casper herbicide | Non ionic surfactant | Spreader90 LF |

Diclofop-methyl | Destro herbicide | Non ionic surfactant | Spreader90 LF |

Ethephon | Incognito 480 | Tank Buffer | Manta Ray |

Glyphosate | Rapid Fire herbicide | Non ionic or ammonium sulphate | Spreader90 LF |

Iodosulfuron-methyl | Duke herbicide | Non ionic surfactant | Spreader90 LF |

Picloram | Slinger herbicide | Non ionic surfactant | Spreader90 LF |

Quinclorac | Quinstar | Methylated seed Oil | BioAAid MSO |

Rimsulfuron | Coliseum herbicide | Non ionic surfactant | Spreader90 LF |

Triclopyr | Slinger 240 | Non ionic surfactant | Scrubwet |

Trifloxysulfuron | Recondo herbicide | Alkylaryl ethoxylates | Agral spray adjuvant or Spreader90 LF |

Fungicides | |||

Thiophanate-methyl + Fluazinam+ | Clean Sweep Trio fungicide | Non ionic surfactant | HydroForce Ultra |

Fosetyl aluminium | Grenadier fungicide | Pigment | Vertmax Duo |

Thiram | Pistol fungicide | Extender - di-1-p menthene | Octane/ Vertmax Duo |

Chlorothalonil | Squadron weatherace | Extender - di-1-p menthene do not use non ionic as can reduce fungicide performance. | Octane/ Vertmax Duo |

Iprodione | Voltar 500SC | Tank buffer | Manta Ray |

Iprodione + Trifloxystrobin | Interface Stressgard | Tank buffer | Manta Ray |

Penthiopyrad | Velista | Alkylaryl ethoxylates - Nonyl phenol or Non Ionic surfactant | |

Insecticides | |||

Abamectin | Malice | Alkylaryl ethoxylates - Nonyl phenol or Non Ionic surfactant | |

Clofentezine | Malice Duo or Apollo | pH buffer or water conditioner | Manta Ray |

Diafenthiuron | Higran | Alkylaryl ethoxylates - Nonyl phenol or Non Ionic surfactant | Agral Label Agral spray aduvant SDS |

FAQ

What does Ammonium Sulphate Adjuvant Do?

Ammonium Sulphate Adjuvant.

- Improves poor quality water to a high standard.

- Acidifies and buffers water. This neutralises the alkalinity and carbonates in water.

- Stops alkaline hydrolysis.

- Improves herbicide movement into plants.

- Ensures high levels of weed death when you use Glyphosate and flowable herbicides.

- Improves the tank compatibility of Glyphosate and Triazine herbicides.

- Improves the performance of chemicals under adverse environmental conditions.

- Crystalline ammonium sulphate is very cost effective.

What Adjuvant is Best for Glyphosate?

In order to know the best adjuvant to use with glyphosate you need to know what affects it.

- Water pH, water quality, temperature and the target all impact how well it works.

- If conditions are cool, use spray grade ammonium sulphate or a non ionic surfactant like OptiSpread 1000.

Factors like water hardness, high pH or mineral content all reduce weed control.

- Hard water affects Glyphosate. Calcium or other cations tend to bind to it. Ammonium sulphate helps counter this.

- Glyphosate works best at a low (more acid) water pH. Buffers like Manta Ray improve its efficacy.

- The final reason to use a spray adjuvant with Glyphosate is if the target is difficult to wet.

Difficult to wet weeds include: Capeweed, Cleavers, Clover, Spurge, Fat Hen, Fleabane, Sowthistle, and Wireweed. With all of these, when you use Glyphosate use a non ionic surfactant to give better results.

What do Spray Adjuvants Do?

Spray adjuvants increase how efficient and effective a spray application is. They improve the performance and physical properties of a spray chemical in three ways:

- They alter how chemicals interact in the spray tank.

- They alter how a product interacts with the target.

- Adjuvants alter how a product moves into the target

When you use the correct product it:

- Improves the coverage and retention of chemicals on target pests.

- Modifies the evaporation rate of your spray.

- Helps retain sprays on target pests when the conditions are not ideal.

- Improves the penetration and the movement of chemicals which improves their performance.

- Adjusts the pH of a spray solution.

- Increases the tank mix compatibility of products.

- Reduces off target damage.

- Reduces spray drift.

How long does pesticide last after mixing?

How long the pesticide lasts after mixing depends on pH, temperature, and to a lesser degree water hardness.The chemical half-life is the amount of time it takes a pesticide to breakdown to half its original concentration. Each half-life that passes reduces the amount of pesticide in the water by one half, i.e. 100% to 50% to 25% to 12.5% to 6.25%, etc.

If you assume a pesticide is 100% effective when you first add it to the spray tank and it has a half-life of 30 minutes, the effectiveness is cut in half every 30 minutes. Ag ood example of this is iprodione which has a half life of 48 mnutes at pH 7. This means that after 48 minutes only 50% of the chemical remains at this pH. After another 48 minutes its half again.

Can i use washing up liquid to make my weedkiller work better?

Do I need an Adjuvant to get a good result?

Any time you apply chemicals, read the label before you use them. This habit should be the same with adjuvants. Even more if you use these with herbicides.

Some products already contain adjuvants, so you do not need to add any more. In fact, if you add more it can result in a loss in performance.

However, if it says on the label to use an adjuvant, you won’t get the best results unless you do.

Good examples of products where you should consider the use of adjuvants include:

- Iprodione-based fungicides such as Voltar 500. Use a spray buffer, like Manta Ray buffer, to reduce the water pH. Iprodione is susceptible to alkaline hydrolysis at a pH of 7 and above.

- Herbicides like the Sulfonylureas. Use a non-ionic surfactant like Scrubwet to give better chemical contact with the leaf.

If I use a spray adjuvant at the label rate, if I add more give better results?

More is not always better. The rates on a label are there for a reason. If you add amounts above the label rate, it will probably cause damage to plants, and result in groundwater pollution.

Can I use pond water, salt water, or well water for a spray tank mix?

Water quality has an impact on the results you get when you use chemicals. The most important quality issues are the water pH and the water hardness.

- You should always use clean water that does not contain suspended soil etc. If you do, ions in the water will tend to neutralise some herbicides and stop them working properly.

- In Australia, tap water is artificially raised to around 8. At this level, it has a negative effect on herbicides like Glyphosate and fungicides like Iprodione. Thats why you should use of a spray buffer or a water conditioner if you use town water with certain chemicals

- Do not use salt water. It contains antagonistic salts and ions that can make a mix useless.

What is the difference between a spray adjuvant and a surfactant?

You add a spray adjuvant to a spray tank to make the active ingredients work better. A surfactant is an adjuvant that improves the dispersal, spreading and wetting of a product.

How can you increase the viscosity of spray mixtures?

There are several products that reduce spray drift and increase the viscosity of a spray mixture. Increasing the viscosity of spray mix is useful when you do not want to get any spray drift into sensitive areas.

How can I tell if products I have not used before can be mixed together?

The product label gives information about adjuvant use. If specific information about the products you want to mix is not on the label, it is wise to contact the manufacturer before you mix anything. If you are still in doubt conduct a jar test, which will let you know if they are compatible.

© 2022, Gilba Solutions Pty Ltd, All rights reserved

References

Jerry Spencer

Jerry has an Hons Degree in Soil Science (1988) from Newcastle Upon Tyne University. He then worked as a turf agronomist for the Sports Turf Research Institute (STRI) until 1993.

He gained a Grad Dip in Business Management from UTS in 1999. He has held a number of technical roles for companies such as Arthur Yates (Commercial Technical Manager) and Paton Fertilizers (Organic, turf specialty and controlled release fertiliser) portfolios.

In 2013 he established Gilba Solutions as independent sports turf consultants and turf agronomists. Jerry has written over 100 articles and two books on a wide range of topics such as Turf Pesticides and turfgrass Nutrition which have been published in Australia and overseas.