Selecting a Turf Fertilizer

Here are some tips to make sure that you get the best result when selecting a turf fertilizer, whether it be slow slow-release or a nitrogen lawn fertilizer. This blog disucusses what fertilizer do professionals use and points you in the right direction to choosing a good fertilizer.

A fertiliser’s physical makeup has a big impact on the performance of any product you apply. There are several important considerations to think about when you develop a fertilizer strategy.

What is a good Fertilizer?

A good fertiliser, whether it be a nitrogen lawn fertilizer or the best lawn fertilizer for Kikuyu grass or couch should have the following characteristics:

- Not cake. By this we mean remain flowable and easy to spread. Some ingredients are not compatible and will form hard “lumps” when mixed together;

- Have the analysis that you need. Many “off-the-shelf” products are just that. They are NPKs that don’t meet your turf requirements. You are better off shopping around to get what you need rather than buying the cheapest product. Fertilizer does vary in quality and so the results you get;

- Do not contain anything that will damage your turf or lawns. For example, a good fertiliser generally does not contain anything likely to burn or damage your turfgrass;

- Contain minimal, if any “filler”. To reduce costs and meet a specific analysis some manufacturers mix in a percentage of low-cost “filler”. This offers no benefit as a fertilizer and simply reduces the cost.

Blended or Compound Fertilizers.

There are so many products to choose from it is very confusing to choose a good fertilizer. One common question professionals ask, when deciding on what fertilizer to use is, are compound fertilizers better than blends?

A compound or complex fertilizer contains two or more nutrients in one homogenous granule so chemically all the granules are the same. Good examples of this are the Nitrophoska range from BASF or many greens grade homogenous NPK fertilizers.

A blend also known as a “salt and pepper” mix is made up of individual nutrients. These are the most common fertilizers on the market as they are a much lower cost than compound or complex fertilizers.

The answer is that there is little difference between quality blended and compound fertilizers.

From both an agronomic and handling perspective the physical make-up of a fertilizer is important. Issues such as “caking”, amount of dust, and poor granule distribution all need to be taken into account. The result needs to be free-flowing, dust-free and stable under a range of conditions.

The Importance of Granule Size.

When choosing a good lawn fertilizer, professionals look at the granule size. Larger granules are thrown further than smaller granules so you can use a wider spread width. Size also has a role in where you can use a product. The reasons for this are:

- It impacts ball roll;

- On low-cut turf larger granules are mown off and go to waste. A small granule is also easier to water in.

- With a smaller granule, you get a more even coverage; this is why pre-emergent combination products like Onset 10GR use a small granule;

- In some cases, a large granule size does not work because it takes too long to break down. Some fertilisers have a low water solubility so they need to be applied in as small a size as possible so they break down. For example, blended fertilisers tend to use a mesh size of 4mm and upwards. At this size, a sulphur granule takes several weeks to oxidize to SO4, while Granomag is even longer.

Another example is agricultural lime as the finer the powder the better the result. This contradicts the belief that coarser lime gives a long-term benefit because it dissolves more slowly.

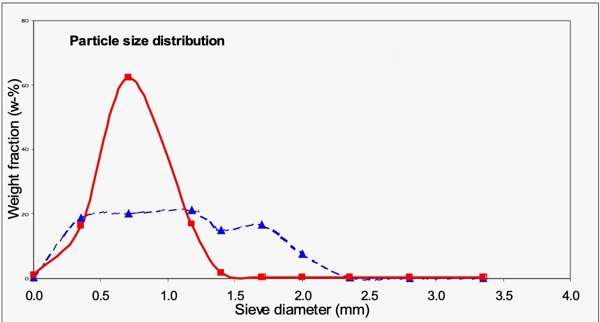

From the perspective of blending, granule size is also important. When blending a good fertiliser, you want a high degree of product uniformity. Blended granules need to have the same upper and lower size limits as well as be the same size between these limits. This ensures that the end product has an even particle size and so spreads well.

Granule Size Metrics.

The SGN stands for size guide number and the higher the number the higher the larger the size. SGN values are the mean granule size multiplied by 100. So Sirflor 38 which has an SGN of 125 has a mean particle size of 1.25mm.

The UI (Uniformity Index) is the ratio of granule sizes representing the smallest 10% and the largest 5% times 100. Values within the range of 40–60 indicate a uniform fertiliser size and the larger the UI value, the more uniform the granule size of a product.

How particle size effects the rate of S oxidization | ||

Particle Size (mesh size/inch) | % S oxidized in 2 weeks | % S oxidized in 4 weeks |

5-10 | 1 | 2 |

10-20 | 2 | 5 |

20-40 | 5 | 14 |

40-80 | 15 | 36 |

80-120 | 36 | 68 |

120-170 | 61 | 81 |

230 | 80 | 82 |

What is Fertilizer Segregation?

Another factor professionals look at when choosing a fertiliser, is segregation. Segregation has a big influence on fertiliser performance and is an important factor to be aware of when choosing a good fertiliser.

The greater the variation in granule size, the greater the risk of segregation. Similar-sized granules behave differently during handling as those with a similar size will tend to congregate together. With segregation, it is the size and not the shape or density that has the most influence.

If all the granules have the same chemical makeup but differ in size, segregation does not affect the chemical uniformity. This is the case with Nitrophoska range.

This variation in granule size means that you can’t apply this evenly. As a guide, granule sizes in a blend should be within 10% of each other. Good fertilisers have better granulation or screening to narrower size ranges.

Granule Hardness in Selecting a Fertilizer.

A good lawn fertilizer should be composed of hard granules. These should be hard enough to not break or form dust when handled. Good granulation requires a degree of sophistication, engineering, and temperature control that only a few producers have.

The Use of Fillers in Selecting a Good Fertilizer

The amount of filler is an important factor when professionals choose a fertiliser. Fillers are often used to bulk out fertiliser and are anything from limestone chips and organic materials to bentonite.

The How Does Critical Relative Humidity (CRH) Impact on Selecting a Fertiliser?

Have you ever opened a bag and it was wet or became wet in hot humid weather? This is due to hygroscopicity and is a result of what is called the critical relative humidity.

The CRH is the temperature above which moisture from the air begins to be absorbed by a fertiliser. The CRH is related to the air temperature and as the air temperature increases, the CRH decreases.

The more hygroscopic a material, the more moisture it will absorb and so the lower the CRH. Blending fertilisers together tends to result in a lower CRH than that of the individual fertilisers and this can result in caking.

Table That Shows the Critical Relative Humidity (CRH) of common fertilizers | |

Fertilizer salt | Critical Relative Humidity |

Calcium nitrate | 46.7 |

Ammonium nitrate | 59.4 |

Urea | 72.5 |

Ammonium sulphate | 79.2 |

Potassium chloride | 84 |

Potassium nitrate | 90.5 |

Monoammonium phosphate (MAP) | 91.6 |

Potassium sulphate | 96.3 |

©, 2022, Gilba Solutions, All rights reserved.

Jerry Spencer

Jerry has an Hons Degree in Soil Science (1988) from Newcastle Upon Tyne University. He then worked as a turf agronomist for the Sports Turf Research Institute (STRI) until 1993.

He gained a Grad Dip in Business Management from UTS in 1999. He has held a number of technical roles for companies such as Arthur Yates (Commercial Technical Manager) and Paton Fertilizers (Organic, turf specialty and controlled release fertiliser) portfolios.

In 2013 he established Gilba Solutions as independent sports turf consultants and turf agronomists. Jerry has written over 100 articles and two books on a wide range of topics such as Turf Pesticides and turfgrass Nutrition which have been published in Australia and overseas.