Using Light for the Best Turf in Shade.

In April of 2021, Comm Bank Stadium was the first Australian stadium to use LED grow lights. SeeGrow LED technology enables turf managers to have a climate-controlled environment with a CO2 canopy to get the best growth and recovery from their turf.

Turf managers use this technology as modern stadium design results in high levels of shade. With the use of traditional turf management practices there is a limit to how much shade turfgrass can tolerate.

The use of these is a game changer, and results in lower turf replacement costs and better quality turf. LED has significantly lower running costs in comparison to HPS rigs, and the results have been nothing short of amazing.

The images below are all taken after 24 to 48 hours of use.

When you use of these LED grow lights it means turf managers are better able to cope with turf in shade.

- A variable light spectrum allows exceptional flexibility to promote top and/or root growth.

- They have an inbuilt irrigation system.

- Each unit has a CO2 canopy to promote growth. You can get up to 10 mm in shoot and root growth in 24 hours.

- In built heaters. The image below is when the canopy temperature was 31°C in comparison to the air temperature of approximately 12°C.

- They are lightweight and two people can easily move them.

What Is The Difference Between LED vs HID Lights?

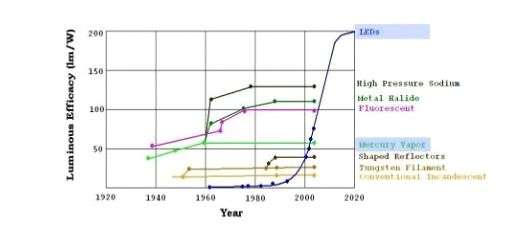

Since their invention in the early 1700s, High-Intensity Discharge (HID) has been the dominant technology used in grow lights. HID put out huge amounts of light, and their spectrum is close enough to the sun to promote plant growth.

You can categorise HID bulbs on the basis of the gas that you use in them.

- The two main types are high-pressure sodium (HPS) and metal halide (MH) lights.

- The type of gas used in the bulb determines the colour spectrum and wavelength.

- Typically, HPS lights are used in the SGL and MLR turf grow lights found at the MCG, and Accor Stadium. These are more towards the red and orange hue.

- In contrast an MH bulb produces a blueish colour, which is useful for the vegetative phase.

However, LEDs are now taking a leading role in this market.

Using Light for Plant Health.

SeeGrow Developments manufacture LED grow lights for stadiums and turf. With the use of these light rigs you get up to 10 mm leaf and root growth in 24 hours.

- SeeGrow use a light spectrum that is specific to the needs of turf. These are specific to the light use of turf grass, rather than simply retro-fitted horticultural lights.

- One of the main advantages of LED over HPS and MH lights is the adjustable spectrum.

- These are in use at Manchester City, Juventus, The San Siro, Tokyo Stadium, Chelsea FC, and Wembley Stadium.

Reasons Why LED is Becoming More Popular.

LED systems have spelt the end of HPS rigs for several reasons:

- LED grow lights last six times as long as HPS.

- They not need reflectors as they have directional lighting.

- LED grow lights contain no toxic metals.

- They are very efficient and use 50 % to 70 % less energy in comparison to HID lights.

- LED needs no cooling and they do not burn turf.

- They use a spectrum that gives the maximum possible chlorophyll absorption. No light goes to waste.

- Turf needs less watering.

- Due to being 2 to 3 times more efficient per m2 in comparison to HPS, turf needs less treatment in operational hours and/or less equipment is required.

- A very low carbon footprint. 9 HPS rigs each use 60 lamps. If you use these for 2,000 (seasonal) hours they produce 800 tonnes of CO2 (800,000 kg). With LED, the savings vary from 200 to nearly 400 % on CO2 emissions.

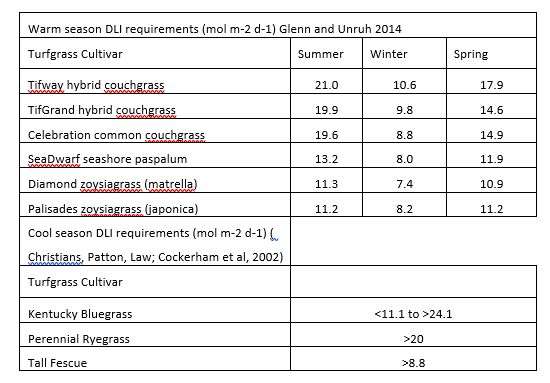

Daily Light Intergral (DLI).

DLI is the cumulative amount of photosynthetic light that is received each day. The DLI measures the number of moles of light (mol) per square meter (m-2) per day (d-1), or mol·m-2·d-1.

The DLI can have a big effect on root and shoot growth. Variations exist between C3 and C4 grasses and also between different cultivars.

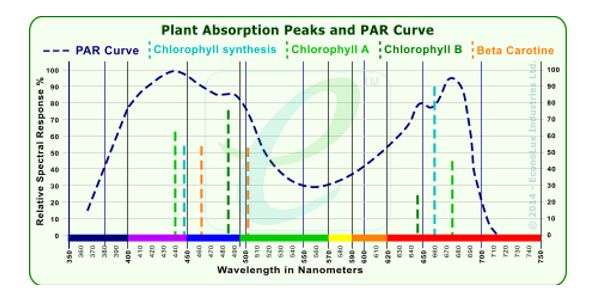

- PAR (Photosynthetically Active Radiation) is a region of the electromagnetic spectrum (400 to 700 nm) that promotes photosynthesis in plants.

- PPF (Photosynthetic Photon Flux) tells us how much PAR a light source emits. PPF does not measure PAR. It tells you how many photons within the PAR region come out of the light source every second.

- PPFD (Photosynthetic Photon Flux Density) measures the number of photons within the PAR region every second. If you have a PAR meter, it is reports PPFD (μmol/m2/s).

What are the Key Differences Between HID and LED?

LED Lasts Six Times as Long.

In a year the output of HPS lamps can degrade by as much as 10 to 15%. When this happens, the spectrum shifts toward the inefficient Green/Yellow range.

LED lasts for at least 50,000 hours with less than a 10% drop in output and has little or no shift in the spectrum.

LED Requires No Reflectors.

HID lamps are very efficient, and HPS lamps run as high as 1.7umol/j (#photons out / joules of energy in).

However, directing the light down to the turf is not efficient, and requires a reflector. The very best reflective materials have only 95% total reflectivity, and this means that every time light strikes the surface, 95% reflects off and 5% absorbs and converts to heat.

With a large diffused source like an HID lamp, it has many reflections. With each reflection, you lose at least 5%, so even the best HID fixtures you only have an efficiency of 85% or less.

That means a 1.7 mmol/joule rating of an HPS lamp is effectively 1.45mmol/joules. Since LEDs are directional they do not require reflectors.

LED Uses No Toxic Metals.

An LED light directly converts electrical energy into visible light.

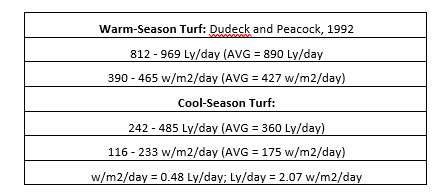

LED Uses 50%-70% Less Energy than HID.

HPS is efficient and produces over 100 lumens per watt. However, with LED’s, the output is greater than 300 lumens per watt. LEDs are showing ever-increasing efficiencies.

LED Needs No Cooling So No Turf Damage.

HID Lamps have an interior wall temperature around 700°C. LED lighting units emit 50% less heat.

HID Has A Fixed Spectrum – Not Ideal For Turf.

Turf absorbs light, and uses the energy to strip the hydrogen out of water. It then combines this Carbon Dioxide in the air to create plant material.

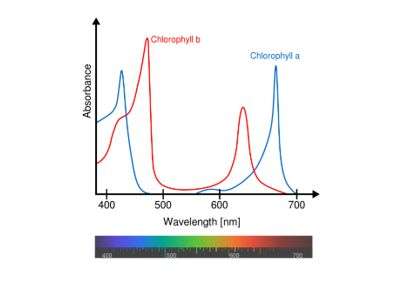

Turf has several pigments that absorb light, and the most important of these is chlorophyll.

Spectrum and Photosynthesis.

Turf converts light into chemical energy. It does this by using chlorophyll to absorb only the blue and red wavelengths of the spectrum.

How Do Plants use Light?

The key to the use of artificial light for turf health is to know how the turf uses it. As the above shows, there are two forms of Chlorophyll (Chlorophyll A and Chlorophyll B).

Each has absorption peaks in both the Red and Blue spectrums, and both reflect yellow and green. While other pigments can absorb the green/yellow bands, over 50% of this spectrum range reflects away and/or is poorly utilized.

Blue light (400 to 500 nm).

Blue light helps regulate the opening of stomata, and acts to prevent etiolated growth. Turf grown under blue light has smaller leaves and shorter stems. Many LEDs for plant applications emit at least a small amount (10-20%) of blue light.

Green light (500 to 600 nm).

Plants appear green because they reflect and transmit slightly more green light than they do blue or red light.

Chlorophyll absorbs green light poorly. It is sometimes claimed that green light is not useful to plants for photosynthesis. However, it is still moderately effective since other pigments do absorb it and use it for photosynthesis.

Red light (600 to 700 nm).

Most LEDs emit a high percentage (75-90%) of red light, that is absorbed by chlorophyll. Red is the most efficient waveband for photosynthesis but turf can become etioliated in the absence of other light wavelengths.

The graph below shows plant absorption over the PAR spectrum range. Absorption around the green/yellow boundary is as low as 30% and from 620 (range/red boundary) to 520 (Blue/Green boundary) it is under 50%.

Other less efficient pigments can absorb and use this spectrum range.

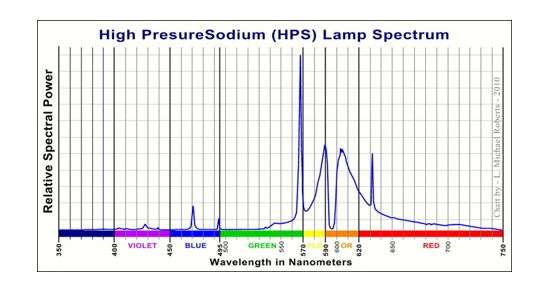

Metal Halide differs from HPS in the fact that the spectrum is produced by individual Metal Halides. When these are heated they turn to gas and emit light.

Metal Halide lamps favour the blue end of the spectrum. As the lamp gets “warmer” in colour, and generates more red light, it gets less efficient, more expensive, and degrades faster.

As you can see from the graphs they still produce small amounts of far red at the critical 675nm Chlorophyll A peak.

LEDs are the only lighting unit technology that meets the specific spectrum for turf grass.

The graph below shows a standard HPS spectrum. You can see from these graphs that most of the HPS spectrum is in the area of the lowest plant absorption.

LED Performance.

Individual LED chips produce very narrow spectrum bands. As a result LED can be mixed to deliver an exact spectrum for the best possible result.

This ability to deliver the light spectrum that turf uses, at a high efficiency and with 30-40% less power has lead to the increase in LED popularity.

Photomorphogenesis.

Photomorphogenesis is how a different light spectrum cause changes in turf characteristics such as leaf and stem size, shape, etc..).

The main influence on this is the ratio of Red : Far red light. Under normal conditions, the R : FR ratio is constant all year round, averaging about 1.15 (Smith, 1982). However, the R : FR ratio can fall to as low as 0.7 at dusk.

One result of photomorphogenesis is a shade stretch response due to turf in shade having a higher proportion of Far Red (FR).

This means that under trees or in shade, turf will begin to stretch and become etoliated. This results in lower in chlorophyll content and the leaves become thinner. You can see this with the naked eye with the turf yellowing.

Jerry Spencer

Jerry has an Hons Degree in Soil Science (1988) from Newcastle Upon Tyne University. He then worked as a turf agronomist for the Sports Turf Research Institute (STRI) until 1993.

He gained a Grad Dip in Business Management from UTS in 1999. He has held a number of technical roles for companies such as Arthur Yates (Commercial Technical Manager) and Paton Fertilizers (Organic, turf specialty and controlled release fertiliser) portfolios.

In 2013 he established Gilba Solutions as independent sports turf consultants and turf agronomists. Jerry has written over 100 articles and two books on a wide range of topics such as Turf Pesticides and turfgrass Nutrition which have been published in Australia and overseas.